Direct-Acting Pressure Regulating Valve

Category: Self-Operated Regulating Valve

Product Details

Overview

The self-operated pressure regulating valve requires no external power source, instead using the energy inherent in the controlled medium itself as its driving force. It introduces an actuator to internally control the position of the valve core, thereby adjusting the pressure difference and flow rate across the valve and maintaining stable pressure either upstream (before the valve) or downstream (after the valve). This type of valve consists of key components such as the valve body, valve core, valve seat, valve stem, diaphragm cover, and sensing element. It features finely segmented pressure ranges that overlap with each other, delivering high precision in pressure regulation. Primarily designed for controlling pressure reduction, pressure relief, and pressure stabilization in media like gases, liquids, and steam, these valves are widely used across various industrial applications—including petroleum, chemical processing, power generation, metallurgy, food production, and light industry equipment.

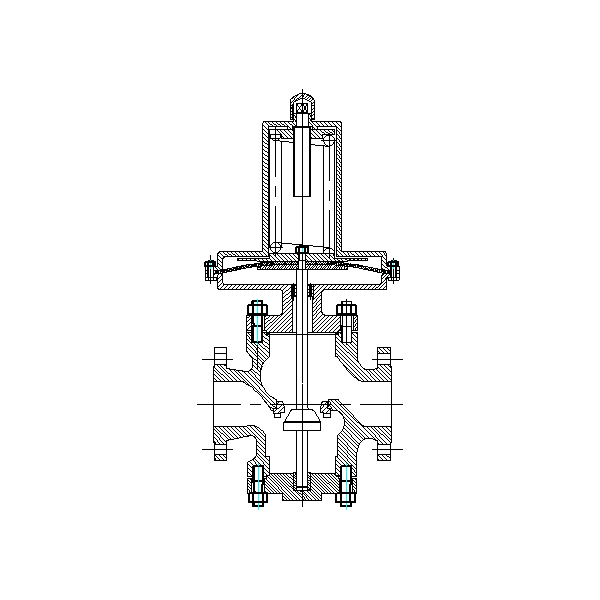

Exterior Drawing

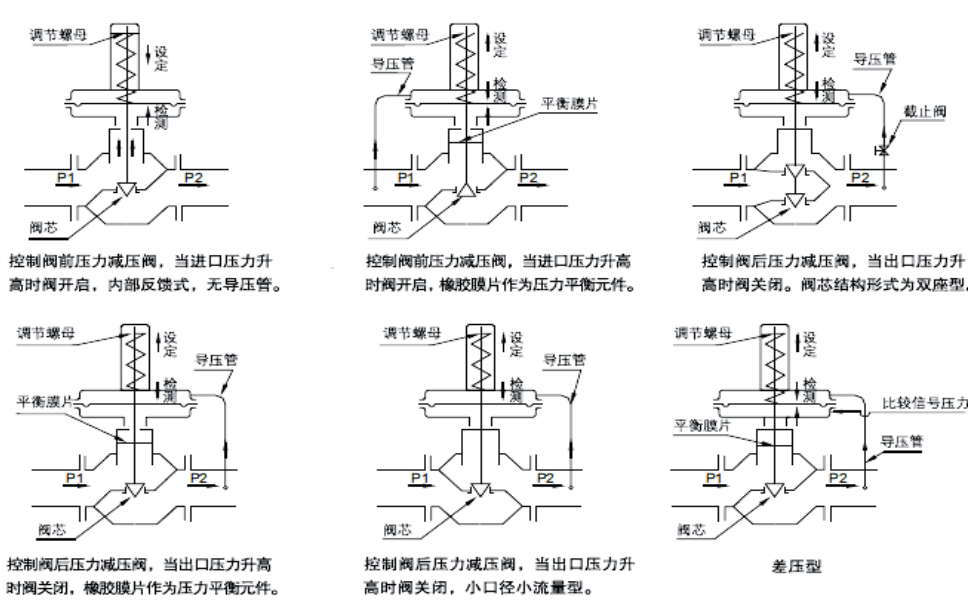

Principles of Stress Regulation

Direct-Acting Pressure Regulating Valve

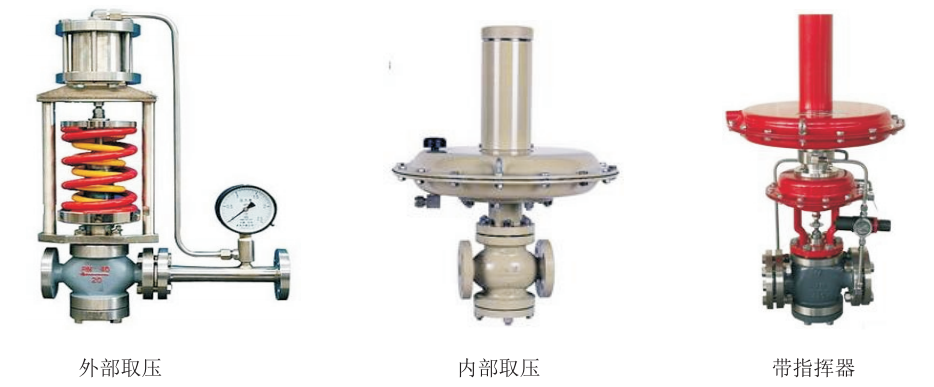

Direct-acting pressure regulating valves are classified into pilot-operated and direct-acting types.

Features of Direct-Acting Shut-Off Type Pressure Regulating Valve

This valve does not require external piping; instead, the medium flows directly from upstream, passes through the valve core and seat for throttling, and then enters the lower diaphragm chamber of the actuator via the upper valve bonnet. The force exerted by the medium on the diaphragm creates a closing tendency for the valve core. Meanwhile, the opposing force from the spring enables the actuator to move, establishing a dynamic equilibrium. By adjusting the regulating screw, the setpoint can be modified to achieve stable pressure control. This valve is ideally suited for applications such as micro-pressure automatic regulation of gases in various industrial furnace combustion systems, petroleum products, storage tank protection gases, and heat treatment protective gases.

Main Technical Parameters

Nominal diameter: DN20–DN100 mm

Nominal pressure: PN 1.0–1.6 MPa, ANSI 125–150

Valve body material: Carbon steel, stainless steel Valve internal parts material: Stainless steel

Flow characteristics: Quick-opening

Flow coefficient: Cv 7–1160

Leakage Level: (Hard) Class IV, (Soft) Class VI Pressure Regulation Range: 0.5 ~ 100 kPa

Connection method: Flanged

Operating temperature: -29°C to +350°C

Features of Direct-Acting Pressure Regulating Valves with Pressure-Opening Mechanism

This valve does not require external piping; instead, the medium flows directly from upstream, passes through the valve core and seat for throttling, and then enters the lower diaphragm chamber of the actuator via the upper valve bonnet. The force exerted by the medium on the diaphragm creates a tendency for the valve core to open. Meanwhile, the opposing force from the spring enables the actuator to move, establishing a dynamic equilibrium. By adjusting the regulating screw, the setpoint can be modified, thereby achieving stable pressure control. This valve is ideally suited for applications such as micro-pressure automatic regulation of gases in various industrial furnace combustion systems, petroleum products, storage tank protection gases, and heat treatment protective gases.

Main Technical Parameters

Nominal diameter: DN20–DN100 mm

Nominal pressure: PN 1.0–1.6 MPa, ANSI 25–150

Valve body material: Carbon steel, stainless steel Valve internal parts material: Stainless steel

Flow characteristics: Quick-opening

Flow coefficient: Cv 7–160

Leakage Level: (Hard) Class IV, (Soft) Class VI Pressure Regulation Range: 0.5 ~ 100 kPa

Connection method: Flanged

Operating temperature: -29°C to +350°C

Keywords: Direct-Acting Pressure Regulating Valve

Previous: No!