Product Details

Overview

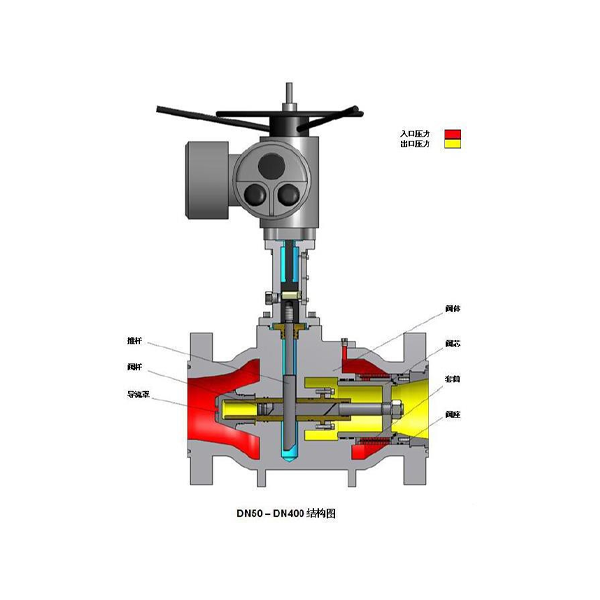

- The axial flow property of the medium Thanks to the use of an axially symmetric flow passage, indirect flows and unnecessary changes in flow direction are completely avoided, maximizing the flow capacity per unit diameter while significantly reducing noise and turbulence. Additionally, this design helps prevent corrosion of the valve by untreated upstream fluids.

- Zero-leakage-level sealing The sealing system features a self-tightening pressure design, where the valve’s seal consists of two sealing rings pre-tightened by a spring. This unique design ensures that, when the valve is closed, the sealing rings are firmly pressed against each other under the upstream fluid pressure, achieving an exceptionally reliable seal.

- Pressure Balance The end face of the piston is evenly equipped with holes, ensuring pressure balance between the inside and outside of the piston. This allows the piston to move smoothly left and right without being affected by the pressure at either end of the valve, enabling rapid actuation even with an actuator structure that requires minimal torque.

- Executive Agency On the piston is a piston rod (valve stem), which features 45°-angled teeth. The piston rod is operated by a pushrod equipped with matching teeth. The pushrod and piston are positioned in perfect perpendicular alignment—when the pushrod moves upward, the valve opens; conversely, when the pushrod moves downward, the valve closes.

Main Technical Parameters

Nominal diameter: DN50 to DN800 mm

Nominal pressure: ANSI 150–1500

Valve body material: WCB, LCC

Valve internal parts material: stainless steel, steel, copper flow

Characteristics: Equal percentage, quick-opening

Flow coefficient: Cv 40–10,289

Leakage Level: Level VI

Adjustable Ratio R: 50:1

Connection method: Flanged

Operating temperature: -29°C to +120°C

How it works

An axial-flow control valve features a straight, symmetrical, and unobstructed flow passage within the valve body—specifically, a direct-flow streamline design. This unique internal cavity design allows the medium to pass through with exceptional ease, ensuring uniform fluid distribution at every point inside the valve. As a result, it minimizes localized high-speed flows, turbulence, and jet-like impacts, significantly enhancing the valve's stability while also reducing turbulence and noise to the greatest extent possible.

Valves are primarily composed of key components such as the valve body, push rod, stem, spool, sleeve, and valve seat. The product achieves regulation of medium pressure and flow by adjusting the relative flow area between the spool and the sleeve, thereby realizing the purpose of throttling control.

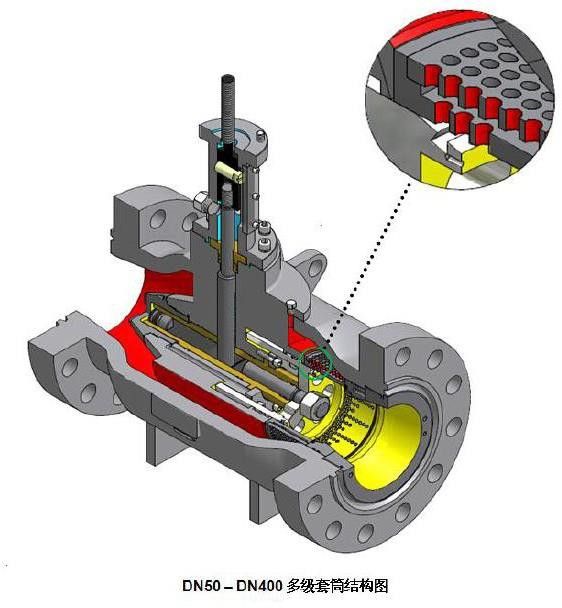

Multi-level Sleeve Structure Diagram

Pressure regulation is achieved through multi-stage pressure reduction, where the fluid passes through a series of small holes in the outer sleeve and expands progressively between the multi-stage sleeves, allowing for controlled flow velocity and managed energy dissipation—resulting in remarkably low noise levels. Meanwhile, pressure regulation is also accomplished by the direct impact of the fluid against the center of the sleeve.

Keywords: Axial-flow control valve