Three-way Diversion Control Valve

Category: Three way Regulating Valve

Product Details

Overview

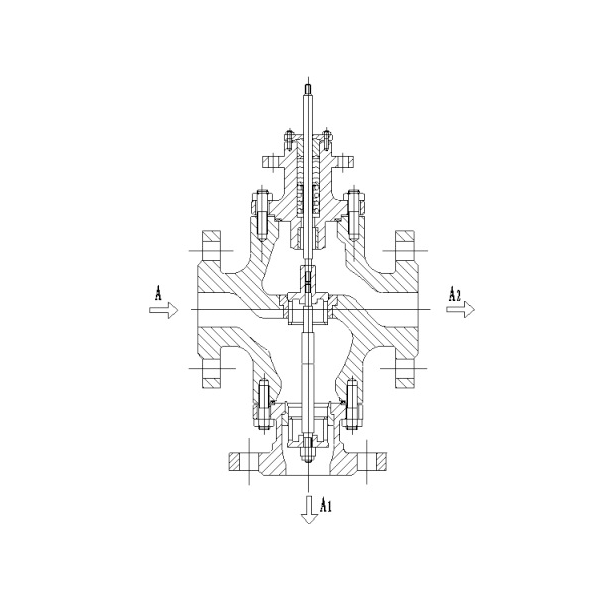

The valve core features a cylindrical design with window openings and is combined with a single-seat valve seat. It consists of components such as the valve body, valve seat, valve core, stem, packing gland, and upper bonnet. This design boasts a compact structure, lightweight construction, sensitive operation, and precise flow characteristics. Like the sleeve in cage valves, the valve core comes in two types of throttling areas: one with large open windows and another with small perforations (jet-type). The latter type effectively reduces noise and minimizes resonance. The three-way control valve incorporates two valve cores and valve seats, featuring a structure similar to that of a double-seat valve. In this configuration, as the flow area between one valve core and its seat increases, the flow area between the other core and its seat decreases—resulting in a fully closed position for one path while the other remains fully open.

The opening and closing of the three-way control valve are achieved by selecting either the direct or reverse action of the actuator. The three-way valve effectively replaces both a fail-open valve and a fail-closed valve, thereby reducing costs and minimizing installation space.

The three-way control valve has three inlets and outlets connected to the pipeline, and is classified into mixing valves and diverting valves based on its function. It primarily controls or switches the proportion of media flowing in either a combined or split manner.

Widely used to precisely control process parameters—such as gases, liquids, and steam—to maintain them at specified values. Suitable for applications in power plants, chemical industries, petroleum, metallurgy, and other fields.

Flow characteristics and fluid direction

| Valve Body Structure |

Usage |

Flow Characteristics |

Executive Agency |

Fluid direction |

| Three-way Confluence Control Valve |

Confluence |

Feature (1) A → AB Feature (2) B → AB |

Positive-acting type |

B → AB |

| Reactive Type |

A → AB |

|||

| Diversion |

Property (1): AB → A Property (2): AB → B |

Positive-acting type |

AB → B |

|

| Reactive Type |

AB → A |

|||

| Three-way Diversion Control Valve |

Diversion |

Feature (1) AB → B Feature (2) AB → A |

Positive-acting type |

AB → A |

| Reactive Type |

AB → B |

Features

The pneumatic/electric three-way control valve divides an incoming fluid stream into two outgoing streams, enabling proportional control or switching of the medium. This type of valve features two outlets and one inlet.

Main Technical Parameters

Nominal diameter: DN80–200 mm

Nominal pressure: PN 1.6–6.34 MPa, ANSI 150–600

Valve body material: Carbon steel, stainless steel, special alloy steel Valve internal parts material: Stainless steel, special alloy steel

Flow characteristics: Linear, Equal Percentage, Quick-Opening; Flow Coefficient: Cv 85–630

Leakage Level: Class IV

Adjustable ratio R: 30:1

Connection method: Flanged

Operating temperature: -29°C to +560°C

Keywords: Three-way Diversion Control Valve

Previous: No!