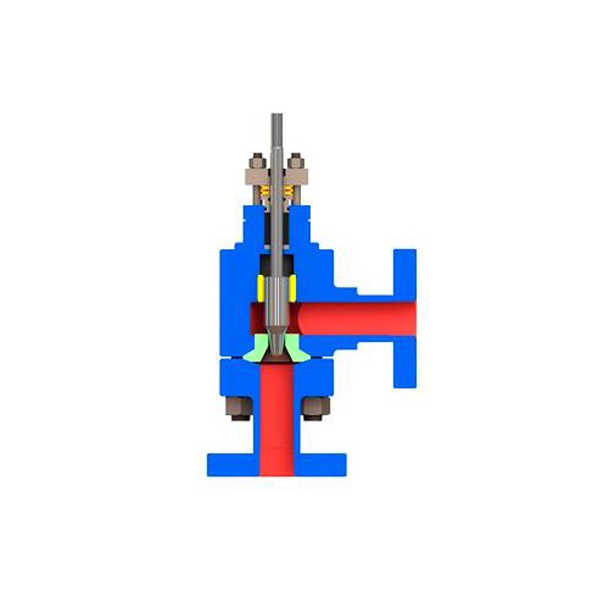

Cage-type angular control valve

Category: Angle Regulating Valve

Product Details

Overview

- The valve features a simple structure, with the valve body's inlet and outlet arranged at a 90° angle. It boasts low flow resistance and high valve capacity, along with a wide adjustability range and highly accurate flow characteristics.

- Due to the angular control valve's dead-corner-free flow passages and straightforward flow path, it features a "self-cleaning" function, making it ideal for applications involving high-viscosity fluids, as well as those containing suspended liquids and particulate matter.

- The angular regulating valve belongs to the single-seat valve category, featuring low leakage. However, since it retains the single-seat design, the larger the diameter, the smaller the allowable pressure difference.

- The flow path is simple and typically used for low-in, side-out configurations, which helps ensure better stability during regulation.

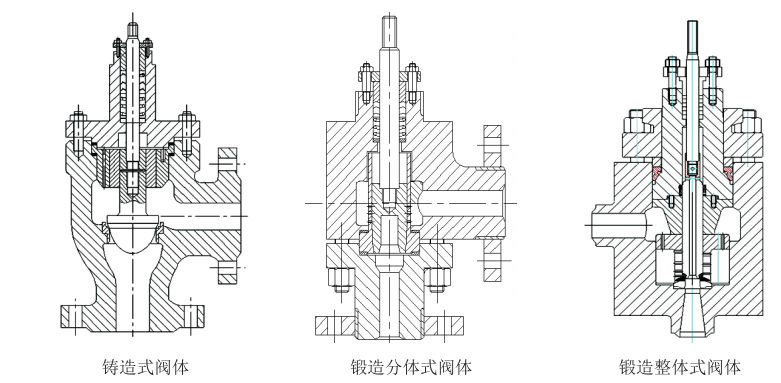

Structural Form

Major Components and Supporting Materials

| Valve |

Components |

Structural Type |

Material |

Note |

| Valve body |

Angular single-seater |

Carbon steel, stainless steel, special alloy steel |

Casting, Forging |

|

| Valve core |

Piston-type, force-balanced valve plug |

Stainless steel, special alloy steel |

Seal surface surfacing and coating |

|

| Valve seat |

O-shaped external thread, sleeve-type |

Stainless steel, special alloy steel |

Seal surface surfacing and coating |

|

| Valve cover |

Room-temperature and heat-dissipation type |

Stainless steel, special alloy steel |

|

|

| Filler |

V-shaped, O-shaped |

PTFE, Flexible Graphite |

|

|

| Sealing gasket |

Serrated, lens-shaped pad |

Stainless steel, special alloy steel |

||

| Executive Agency |

Pneumatic diaphragm multi-spring type, cylinder |

Spring range (kPa): 20–100, 40–200, 80–240, 120–240 |

||

| Input signal (kPa): 150–400; Positioner 4–20 mA DC, 1–5 V |

||||

| All-electronic 3610L, PS Series |

Input signal 4–20 mA.DC, wiring 2-1/2 NPT |

|||

Features

The flow path is simple, with the inlet and outlet arranged at a 90° angle, resulting in low flow resistance and excellent flow capacity—while also inheriting the advantages of cage-type control valves. It is primarily suited for controlling applications involving large pressure differences, high-viscosity fluids, and impure media containing suspended solids or particulates.

Main Technical Parameters

Nominal diameter: DN40–DN200 mm

Nominal pressure: PN1.6–6.4 MPa, ANSI 150–600

Flow characteristics: Linear, equal percentage, quick-opening; Flow coefficient: Cv 11–850

Leakage Level: Class III, Adjustable Ratio R: 50:1

Connection method: Flanged, welded Operating temperature: -29°C to +560°C

Keywords: Cage-type angular control valve