Product Details

Overview

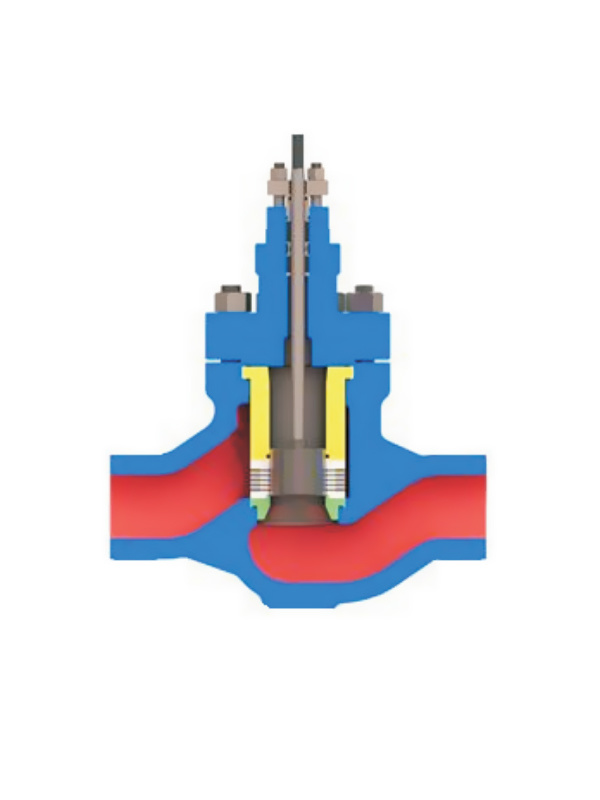

The valve features an advanced and well-designed structure, with seamlessly integrated curved flow passages that minimize flow resistance while maintaining strong throughput capability. It consists of components such as the valve body, valve bonnet, valve plug, sleeve, stem, and packing gland.

The valve plug is guided by a sleeve and automatically self-aligns. With its large guiding area, the valve plug exhibits strong vibration resistance, ensuring smooth operation and high adjustment accuracy.

The sleeve is securely fixed inside the valve chamber using a compression-type mechanism, making assembly and disassembly simple and maintenance convenient.

The unique cage design is suitable for demanding operating conditions such as flash and cavitation, and also ideal for controlling clean fluids under significant pressure differentials.

Structural Form

Major components and supporting materials

| Valve | Components | Structural Type | Material Kit | Note |

| Valve body | Straight-through single-seat spherical body | Carbon steel, stainless steel, alloy steel | Casting, forging, welding | |

| Valve core | Piston-type | Stainless steel, special alloy steel | Special requirement: Surfacing welding or spray coating treatment | |

| Valve seat | Sleeve-type | Stainless steel, special alloy steel | Special requirement: Surfacing welding or spray coating treatment | |

| Upper Valve Cover | Room-temperature, elongation-type heat dissipation, metal bellows type | Carbon steel, stainless steel | The amount of elongation varies depending on the temperature. | |

| Filler | V-shaped, O-shaped | PTFE, Flexible Graphite | ||

| Sealing gasket | Serrated, sealed envelope ring | Stainless steel, special alloy steel, flexible graphite | ||

| Executive Agency | Pneumatic diaphragm multi-spring type, cylinder | Spring range (kPa): 20–100, 40–200, 80–240, 120–240 | ||

| Input signal (kPa): 150–400; Positioner 4–20 mA DC, 1–5 V | ||||

| Entirely electronic models 3610L, 3810L, and the PS series | Input signal 4–20 mA.DC, wiring 2-1/2 NPT | |||

Features

This valve is a pressure-balanced type specifically designed for demanding high-temperature and high-pressure operating conditions. It is suitable for applications where leakage requirements are not stringent, primarily used in industries such as thermal power plants and steam boilers.

Main Technical Parameters

Nominal diameter: DN40–DN300 mm

Nominal pressure: PN10–42 MPa, ANSI 900–2500

Valve body materials: Carbon steel, stainless steel, special alloy steel

Valve internal parts material: Stainless steel, special alloy steel

Flow characteristics: Linear, equal percentage, quick-opening

Flow coefficient: Cv 12–1440

Leakage Level: Class III

Adjustable Ratio R: 50:1

Connection methods: Flanged, Welded

Operating temperature: -29°C to +560°C

Keywords: High-Pressure Cage-Type Control Valve

Previous: No!