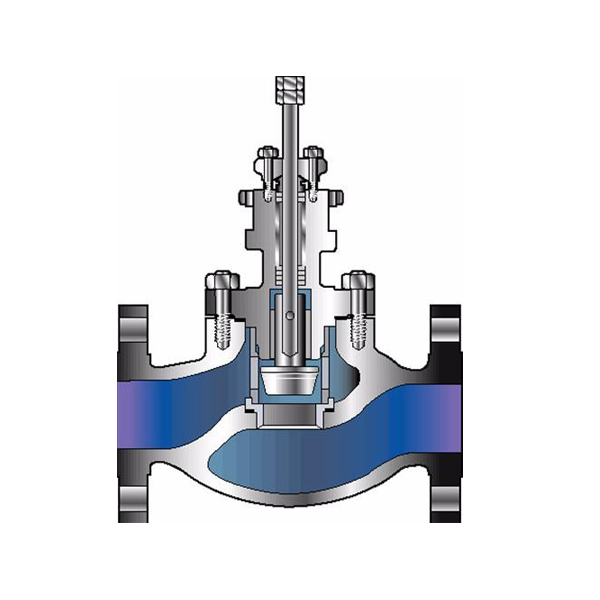

Sleeve Single-Seat Control Valve

Category: Single Seat Regulating Valve

Product Details

Overview

- The valve features a simple structure and a straight-through, arc-shaped flow path, ensuring excellent flow capacity. It consists of components such as the valve body, valve seat, valve core, stem, packing gland, and bonnet. The flow path is designed in an S-shaped streamline, offering minimal pressure drop loss, high flow rate, and a wide adjustable range.

- The valve core is equipped with a dedicated guide sleeve, featuring a large guiding area and excellent vibration resistance for smooth operation. The valve seat and valve core are precisely aligned, ensuring high adjustment accuracy. Depending on the specific application requirements, it can be fitted with either a pneumatic or electric actuator, offering advantages such as a compact design, small footprint, lightweight construction, substantial output force, and highly responsive performance.

- Due to the valve's design, which features only one valve core and valve seat, the valve core experiences a significant unbalanced force during fluid flow. Therefore, this series of valves is primarily suited for applications where minimal leakage is permitted and where the pressure difference between the valve's upstream and downstream sides is relatively small. They can be widely used to control fluids under a variety of different pressure and temperature conditions.

Structural Form

Flow Characteristics

Major Components and Supporting Materials

| Valve |

Components |

Structural Type |

Material package |

Note |

| Valve body |

Straight-through single-seat spherical body |

Carbon steel, stainless steel, alloy steel |

Casting, forging, welding |

|

| Valve core |

Plunger Parabola |

Stainless steel, special alloy steel |

Special requirement: Surfacing welding or spray coating treatment |

|

| Valve seat |

O-type external thread |

Stainless steel, special alloy steel |

Special requirement: Surfacing welding or spray coating treatment |

|

| Valve cover |

Room-temperature, elongation-type heat-dissipating metal corrugated pipe |

Carbon steel, stainless steel |

The length of expansion varies depending on temperature levels. |

|

| Filler |

V-shaped, O-shaped |

PTFE, Flexible Graphite |

|

|

| Sealing gasket |

Serrated |

Stainless steel, special alloy steel |

|

|

| Guidance Ring |

Split-type, integrated type |

Carbon steel, stainless steel, alloy steel |

Split-type bushing |

|

| Executive Agency |

Pneumatic diaphragm multi-spring type, cylinder |

Spring range (kPa): 20–100, 40–200, 80–240, 120–240 |

||

| Input signal (kPa): 150–400; Positioner: 4–20 mA DC, 1–5 V |

||||

| Entirely electronic models 3610L, 3810L, and PS series |

Input signal 4–20 mA.DC, wiring 2-1/2 NPT |

|||

Features

The valve seat features a sleeve-type opening structure, allowing both the sleeve and the valve core to provide dual-stage regulation of the medium, thereby minimizing damage to the valve's internal components caused by flash vaporization, cavitation, and erosion. This valve is ideally suited for applications requiring excellent shut-off performance and clean fluid control in environments where cavitation is likely to occur.

Main technical parameters Main technical parameters

Nominal diameter: DN25 to DN250 mm

Nominal pressure: PN 1.6–6.4 MPa, ANSI 125–600

Flow characteristics: Linear, equal-percentage; Flow coefficient Cv: 0.01–400

Leakage Class: (Hard Seal) Class IV, (Soft Seal) Class VI; Adjustable Ratio R: 30:1

Connection methods: Flanged type, welded type

Operating temperature: -196°C to +560°C

Keywords: Sleeve Single-Seat Control Valve

Previous: High-Pressure Single-Seat Control Valve