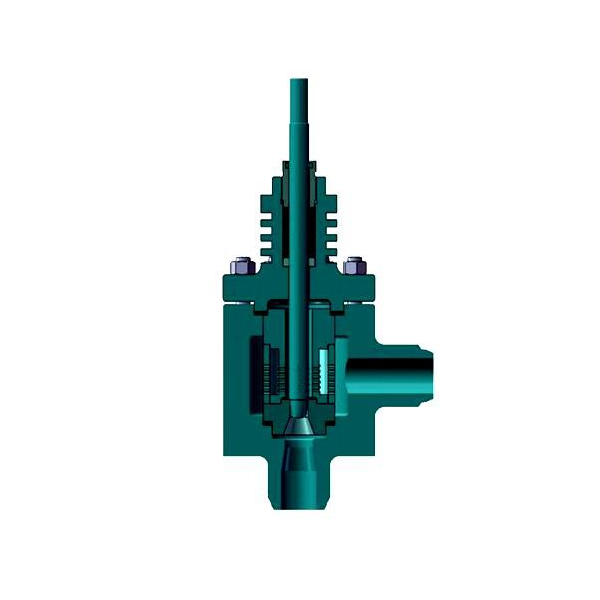

High-Pressure Differential Angular Control Valve

Category: Angle Regulating Valve

Product Details

Overview

- The valve features a simple structure, with the valve body's inlet and outlet arranged at a 90° angle. It boasts low flow resistance and high valve capacity, along with a wide adjustability range and excellent flow characteristic accuracy.

- Due to the angular control valve's dead-corner-free flow passages and simple flow path, it features a "self-cleaning" function, making it ideal for applications involving high-viscosity fluids, as well as fluids containing suspended liquids and particulate matter.

- The angular regulating valve belongs to the single-seat valve category, featuring low leakage. However, since it retains the single-seat design, the allowable pressure difference decreases as the diameter increases.

- The flow path is simple and typically used with a low-in, side-out configuration, which helps ensure better stability during regulation.

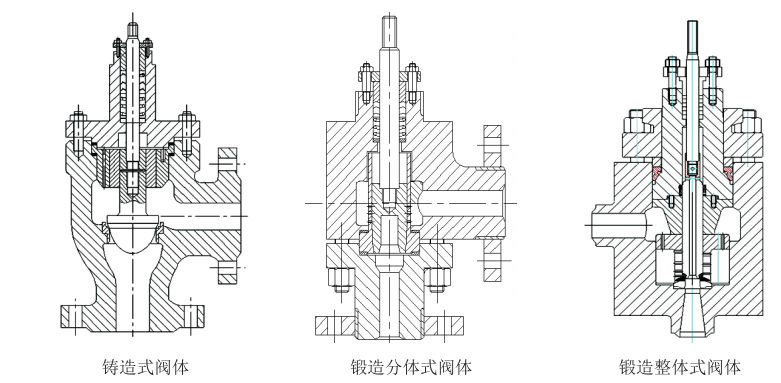

Structural Form

Major Components and Supporting Materials

| Valve |

Components |

Structural Type |

Material |

Note |

| Valve body |

Angular single-seater |

Carbon steel, stainless steel, special alloy steel |

Casting, Forging |

|

| Valve core |

Piston-type, force-balanced valve plug |

Stainless steel, special alloy steel |

Seal surface surfacing and spraying |

|

| Valve seat |

O-shaped external thread, sleeve-type |

Stainless steel, special alloy steel |

Seal surface surfacing and spraying |

|

| Valve cover |

Room-temperature and heat-dissipation type |

Stainless steel, special alloy steel |

|

|

| Filler |

V-shaped, O-shaped |

PTFE, Flexible Graphite |

|

|

| Sealing gasket |

Serrated, lens-shaped pad |

Stainless steel, special alloy steel |

||

| Executive Agency |

Pneumatic diaphragm multi-spring type, cylinder |

Spring range (kPa): 20–100, 40–200, 80–240, 120–240 |

||

| Input signal (kPa): 150–400; Positioner: 4–20 mA DC, 1–5 V |

||||

| All-electronic 3610L, PS Series |

Input signal 4–20 mA.DC, wiring 2-1/2 NPT |

|||

Features

The valve's throttling component employs a multi-stage pressure-reducing cavitation-resistant design. The valve body features an upper-mounted structure, while the valve seat incorporates a multi-layered, pressure-reducing sleeve design to protect the valve body from damage caused by flash vaporization and cavitation. Additionally, the valve core and seat are built with ST alloy overlay welding, providing excellent resistance against erosion. As high-pressure fluid flows from the inlet to the outlet of the throttling assembly, both its pressure and pressure drop gradually decrease in a controlled manner, effectively preventing cavitation and erosion. This valve is ideally suited for applications in the chemical, petrochemical industries, as well as scenarios requiring high cavitation resistance.

Main Technical Parameters

Nominal diameter: DN6–DN100 mm

Nominal pressure: PN42MPa or higher, ANSI 2500

Valve body material: Forged stainless steel

Valve internal parts material: Forged stainless steel + ST

Flow characteristics: Linear, equal percentage, quick-opening; Flow coefficient: Cv 1–60

Leakage Level: Class IV, Adjustable Ratio R: 30:1

Connection method: Flanged, welded. Operating temperature: -46°C to +300°C

Keywords: High-Pressure Differential Angular Control Valve

Previous: No!