Control Valve Failure Analysis and Solutions

Category: Company Training

Time:2025-04-26

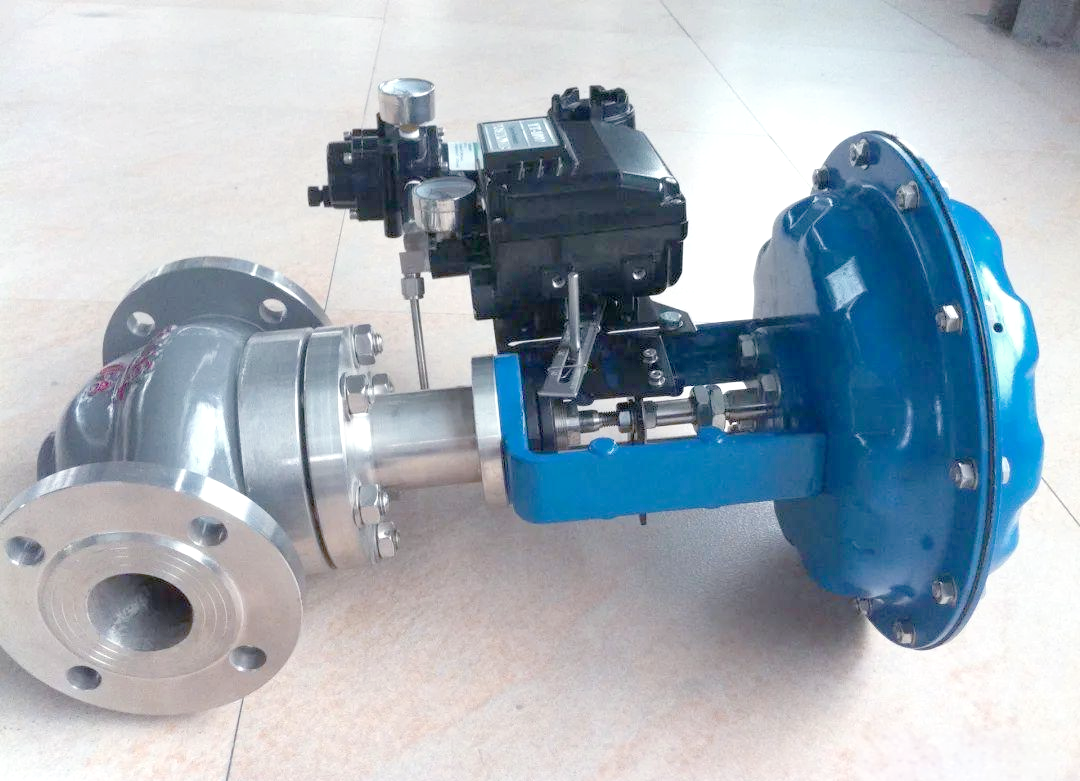

Control valves play a critical role in industries such as petrochemicals, pharmaceuticals/biotechnology, and new energy/new materials, primarily used in critical applications like precise control and emergency shut-off. To ensure optimal performance, accurate calculation and proper selection are essential, while correct installation and commissioning are equally vital. Any issues during the selection, installation, or debugging of a control valve will inevitably compromise its functionality. Therefore, gaining a deep understanding of how these valves operate—and mastering the skills needed for effective maintenance—is particularly important. Moving forward, we’ll delve into common failures of pneumatic control valves and explore the corresponding troubleshooting methods. A broadly defined pneumatic control valve encompasses pneumatic regulating valves and pneumatic on-off valves, all powered by compressed air. These valves utilize actuators such as cylinders and diaphragms, often combined with accessories like valve positioners, solenoid valves, and limit switches, to achieve either switching or continuous control functions. Pneumatic control valves can experience a wide variety of failure modes, including common issues such as internal leakage, external leakage, valve sticking or failure to actuate, significant fluctuations in valve opening, jamming, and poor control accuracy. Such failures may arise from multiple factors, including inherent defects in the valve body, cylinder malfunctions, inaccuracies in the positioner, failures of auxiliary components like solenoid valves, DCS system malfunctions, problems with control cables, inadequate maintenance and timely servicing, inherent quality flaws in the valve itself, errors in selection or design, or even damage to pneumatic components. I. Valve Body Failure and Corresponding Strategies

The valve body is the core component of a pneumatic control valve, and its failure can directly affect the valve's proper operation. Common valve body issues include internal leakage, inability to actuate, and significant fluctuations in opening degree. To address these problems, we need to implement appropriate countermeasures, such as inspecting the valve body for damage, ensuring proper connection between the valve body and the actuator, and regularly cleaning and lubricating the valve body— all aimed at maintaining stable valve performance.

1) If the metal seat of a butterfly valve is damaged, it may cause the valve body to jam and become immobile. Similarly, if the retaining pin of the butterfly valve comes loose, or if the bolt connecting the ball valve’s stem to its core slips out of thread, the valve stem might appear to be moving, but the valve core will actually remain stationary.

2) Wear inside the ball valve body can cause the valve to stick easily or move sluggishly, while damage to the ball valve's soft sealing gasket may lead to internal leakage or sticking issues.

3) If the valve stem bushing of the half-ball valve is damaged, it will create difficulties for the valve's proper operation.

4) The valve stem seals of steam valves may degrade due to high temperatures, leading to steam leaks. Meanwhile, if the silencer plate on the steam valve comes loose, it can not only cause the valve to jam frequently but also result in significantly increased noise levels in the piping system.

5) Wear or corrosion inside the valve stem can lead to internal leakage in the valve; similarly, damage to the seals at the valve stem packing area can also cause leakage issues.

Causes and Countermeasures

When discussing the issue of internal valve leakage, we analyzed two possible causes: first, wear or corrosion inside the valve stem, which can compromise the valve's sealing performance; and second, damage to the seals at the valve stem packing area, a common reason for leaks as well. To address these issues, we need to implement appropriate measures to prevent and resolve internal valve leakage.

1) The causes of leakage in the valve stem and seat may include wear or corrosion on the surfaces, insufficient actuator force, and loosening due to thread wear in the seat. To address this, improve the grinding of the mating surfaces, adjust the connection between the actuator and the valve stem, or tighten the bolts—and if necessary, replace the valve stem and seat altogether.

2) Leakage between the valve seat ring and the valve body may occur due to insufficient tightening torque, poor surface finish of the valve body, improper gasket selection, or the presence of small holes and burrs on the valve body. Mitigation measures include increasing the tightening force, thoroughly cleaning and treating the valve body, replacing it with a suitable gasket, and re-welding the valve body if necessary.

3) Packing leakage typically occurs due to poor valve stem finish or bending, insufficient tightening of the packing gland, improper packing type, excessive stacking of packing layers, or corrosion pits and deformation damage in the packing. Remedial measures include polishing the valve stem and straightening any bends, retightening or replacing the packing, installing spacer rings to reduce layer height, substituting with higher-performance packing materials, and repairing or replacing components such as the gland follower and flange bolts.

4) Valve stem and valve vibration can cause the connection between the valve stem and its components to loosen or even break, potentially due to excessive torque or improper pin connections. To address this issue, consider switching to an integral valve stem and core assembly or welding the valve core directly into place—this will ensure a secure connection and help eliminate vibration altogether.

On the other hand, valve vibration may result from issues such as leakage in the sealing packing, improperly adjusted bypass valves, excessively high controller gain, unstable valve support, or the presence of external vibration sources. Appropriate corrective actions include lubricating and readjusting the packing, re-calibrating the bypass system, selecting a low-gain controller, securely mounting the valve, and positioning it away from any potential vibration sources.

II. Causes of Cylinder Failure and Countermeasures

Frequently Asked Questions

1) If the limit bolts in the actuator come loose, it can cause air leakage in the cylinder, which in turn affects the proper operation of the valve—and may even prevent it from reaching the intended opening position.

2) Once the O-ring seal in the cylinder is damaged, it can also lead to air leakage, making the valve operation difficult—or even completely preventing it from moving altogether.

3) If the linkage mechanism that drives the valve body via the cylinder becomes loose or rusted, it will make the valve operation more difficult.

4) Valve operation can also become difficult when the cylinder capacity is too small or if the cylinder spring malfunctions.

Next, we will explore corresponding solutions for these possible causes.

1) Possible causes of leakage at the piston seal include insufficient cylinder surface finish, improper installation of piston rings, or damage to the sealing rings due to operation under high-temperature conditions or prolonged use. To address these issues, we can take the following measures: regrind the cylinder and readjust the stop bolts; select appropriate sealing rings based on the actual operating temperature; and ensure proper installation when replacing them.

2) If the cylinder limit bolts become loose, they should be retightened to ensure stability.

3) When piston friction increases, it can be reduced by reapplying lubricant, as well as cleaning and lapping the cylinder and piston.

4) If the valve doesn’t operate smoothly or fail to reach its intended stroke, it could be due to insufficient preload on the actuator spring, a damaged spring, or inaccurate positioning of the limit block. In this case, we’ll need to calibrate, readjust, or replace the spring—and ensure the limit block is correctly aligned.

III. Causes of Equipment Failure and Countermeasures

Common faults and their troubleshooting methods

1) If the positioner is not functioning properly, it could be due to an issue with either the sensor or the actuator, or perhaps a malfunction within the positioner itself. In this case, we need to inspect the operational status of both the sensor and the actuator to identify any faults, and then implement appropriate repair measures to address the problem.

2) The locator is experiencing drift, which may be caused by external environmental interference or internal circuit issues. We can try adjusting the locator's sensitivity or gain to minimize the impact of external factors, while also inspecting the internal circuits to ensure they are functioning properly and maintaining the device's stability.

3) The locator display may be inaccurate due to incorrect sensor readings or issues with internal data processing. In this case, we need to recalibrate the sensor and verify that the data-processing algorithm is functioning correctly to ensure the accuracy of the locator display.

Through the above measures, we can effectively address various potential malfunctions that may occur during the locator's operation, ensuring it functions reliably and accurately.

1) A malfunction in the positioner circuit board can cause the valve to operate improperly.

2) Damage or wear to the small slide valve often results from insufficient cleanliness of the instrument air or the ingress of contaminants into the positioner, which in turn affects the valve's proper operation.

3) Damage to the proportional valve in the positioner can also lead to abnormal valve operation.

4) Damage to the sliding rheostat typically occurs due to excessively high ambient temperatures and the ingress of liquids like water into its internal components, which can lead to inaccurate valve positioning and abnormal operation.

5) If the O-ring at the air supply port of the positioner breaks, it will impede the movement of the small spool valve stem, causing the valve to fail to operate properly.

6) The gland connection of the locator has poor sealing, which could lead to moisture damage on the circuit board.

7) Severe pipe vibrations, excessively high ambient temperatures, and humidity can all lead to circuit board failures.

8) The gland head was not sealed tightly, allowing water to enter the locator and subsequently damaging the circuit board. To resolve this issue, reinforce the sealing performance of the gland head to prevent water from seeping into the locator.

9) High humidity and excessive dust in the instrument air cause dirt to enter the small slide valve, leading to wear and ultimately affecting the valve's proper operation. The recommended countermeasure is to install an additional air filter to improve the quality of the instrument air.

10) High ambient temperature, excessive humidity, and severe vibrations frequently cause the sliding rheostat and circuit board to fail. The solution is to separate the circuit board from the small slide valve and the sliding rheostat, designing a modular valve positioner instead.

11) The O-ring seal on the positioner is prone to cracking, which can cause the small spool valve stem to become stuck. This typically occurs due to excessively high air supply pressure—normal air supply pressure should be maintained around 0.5 MPa. To prevent this issue, the air supply pressure should be kept at approximately 0.4 MPa, and higher-quality seals should be selected.

IV. Failures Caused by Process and Design Factors, Along with Corresponding Countermeasures

Factors related to process and design can also lead to valve positioner failures. While these issues may not be as immediately obvious as mechanical or electrical faults, they still deserve careful attention. To ensure the reliable operation of valve positioners, we need to monitor these process- and design-induced failures closely and implement appropriate measures to prevent and address them effectively.

1) Fluctuations in process parameters caused the pipeline pressure differential to exceed normal ranges, resulting in the valve failing to operate properly.

2) Media factors cause scaling inside the valve body, leading to unstable valve operation.

3) Pipe blockage is another common reason why valves fail to operate smoothly.

4) Due to improper design selection, the selected actuator lacks sufficient torque to properly operate the valve. Additionally, the inappropriate choice of valve body material may also lead to damage to the valve body during operation.

5) When the control valve experiences excessive pressure differential and fails to open properly, an effective solution is to install a bypass valve on both the upstream and downstream sides of the control valve.

6) If valve body scaling occurs due to process issues, potentially affecting the proper opening of the control valve, you can install an additional flushing pipe and periodically disassemble the valve for cleaning. If necessary, the valve core may also need to be ground or polished.

7) If a pipeline blockage is hindering the operation of the control valve, optimize your operating procedures to minimize the likelihood of pipe clogging. Alternatively, disassembling the pipeline to flush the valve is also an effective solution.

8) For design selection issues, all process parameters should be thoroughly optimized during the design phase to ensure that inaccurate process parameters do not lead to problems when making the final selection.

V. DCS System-Related Failures and Corresponding Mitigation Strategies

FAQ Collection

As the core of modern industrial automation control, the stability of DCS systems is critical to production processes. However, due to various factors, DCS systems can occasionally experience failures, disrupting smooth operations. This article will explore common faults caused by DCS systems, along with their corresponding troubleshooting solutions, equipping you with the tools to better address and prevent these issues.

1) The I/O card is damaged, resulting in no signal output and, consequently, the control valve failing to operate.

2) Instability in the DCS output signal can cause fluctuations in the control valve opening, thereby affecting its proper operation.

6. Pneumatic Component Failures and Corresponding Mitigation Strategies

Pneumatic components are critical elements in control valve systems, and their damage or failure can directly affect the proper operation of the valves. To ensure stable system performance, it’s essential to implement effective strategies for preventing and addressing these issues.

1) Aging or damage to the air supply hose, or leaks in the stainless steel air supply pipe, can result in insufficient air pressure, which in turn affects the proper operation of the control valve.

2) If the air filter breaks or its filter element becomes excessively dirty, it can also interfere with the smooth operation of the control valve.

3) Insufficient air supply pressure, or the air source simply not being turned on, is also a common cause of abnormal control valve operation.

To address these potential issues, we propose the following strategies:

1) Regularly inspect the condition of gas supply hoses and stainless steel gas lines, promptly replacing any aged or damaged components to ensure stable gas pressure.

2) Ensure the air filter remains intact and regularly clean or replace the filter element to maintain the precise operation of the control valve.

3) Continuously monitor the air supply pressure to ensure it remains within the normal range, and verify that the air source is properly activated, thereby maintaining stable operation of the control valve.

In response to the issues mentioned above, we can implement the following measures for improvement:

1) Replace the air supply hose or air filter with higher-quality components, and establish a regular inspection schedule. If any damage, air leakage, or excessive dirt is detected in the air supply hose, air filter, or filter element, immediate replacement should be carried out to ensure proper operation of the control valve.

2) Adjust the air supply pressure to reach the minimum required by the pneumatic valve, ensuring stable operation of the control valve.

Causes and Countermeasures

When discussing the issue of internal valve leakage, we analyzed two possible causes: first, wear or corrosion inside the valve stem, which can compromise the valve's sealing performance; and second, damage to the seals at the valve stem packing area, a common reason for leaks as well. To address these issues, we need to implement appropriate measures to prevent and resolve internal valve leakage.

1) The causes of leakage in the valve stem and seat may include wear or corrosion on the surfaces, insufficient actuator force, and loosening due to thread wear in the seat. To address this, improve the grinding of the mating surfaces, adjust the connection between the actuator and the valve stem, or tighten the bolts—and if necessary, replace the valve stem and seat altogether.

2) Leakage between the valve seat ring and the valve body may occur due to insufficient tightening torque, poor surface finish of the valve body, improper gasket selection, or the presence of small holes and burrs on the valve body. Mitigation measures include increasing the tightening force, thoroughly cleaning and treating the valve body, replacing it with a suitable gasket, and re-welding the valve body if necessary.

3) Packing leakage typically occurs due to poor valve stem finish or bending, insufficient tightening of the packing gland, improper packing type, excessive stacking of packing layers, or corrosion pits and deformation damage in the packing. Remedial measures include polishing the valve stem and straightening any bends, retightening or replacing the packing, installing spacer rings to reduce layer height, substituting with higher-performance packing materials, and repairing or replacing components such as the gland follower and flange bolts.

4) Valve stem and valve vibration can cause the connection between the valve stem and its components to loosen or even break, potentially due to excessive torque or improper pin connections. To address this issue, consider switching to an integral valve stem and core assembly or welding the valve core directly into place—this will ensure a secure connection and help eliminate vibration altogether.

On the other hand, valve vibration may result from issues such as leakage in the sealing packing, improperly adjusted bypass valves, excessively high controller gain, unstable valve support, or the presence of external vibration sources. Appropriate corrective actions include lubricating and readjusting the packing, re-calibrating the bypass system, selecting a low-gain controller, securely mounting the valve, and positioning it away from any potential vibration sources.

II. Causes of Cylinder Failure and Countermeasures

Frequently Asked Questions

1) If the limit bolts in the actuator come loose, it can cause air leakage in the cylinder, which in turn affects the proper operation of the valve—and may even prevent it from reaching the intended opening position.

2) Once the O-ring seal in the cylinder is damaged, it can also lead to air leakage, making the valve operation difficult—or even completely preventing it from moving altogether.

3) If the linkage mechanism that drives the valve body via the cylinder becomes loose or rusted, it will make the valve operation more difficult.

4) Valve operation can also become difficult when the cylinder capacity is too small or if the cylinder spring malfunctions.

Next, we will explore corresponding solutions for these possible causes.

1) Possible causes of leakage at the piston seal include insufficient cylinder surface finish, improper installation of piston rings, or damage to the sealing rings due to operation under high-temperature conditions or prolonged use. To address these issues, we can take the following measures: regrind the cylinder and readjust the stop bolts; select appropriate sealing rings based on the actual operating temperature; and ensure proper installation when replacing them.

2) If the cylinder limit bolts become loose, they should be retightened to ensure stability.

3) When piston friction increases, it can be reduced by reapplying lubricant, as well as cleaning and lapping the cylinder and piston.

4) If the valve doesn’t operate smoothly or fail to reach its intended stroke, it could be due to insufficient preload on the actuator spring, a damaged spring, or inaccurate positioning of the limit block. In this case, we’ll need to calibrate, readjust, or replace the spring—and ensure the limit block is correctly aligned.

III. Causes of Equipment Failure and Countermeasures

Common faults and their troubleshooting methods

1) If the positioner is not functioning properly, it could be due to an issue with either the sensor or the actuator, or perhaps a malfunction within the positioner itself. In this case, we need to inspect the operational status of both the sensor and the actuator to identify any faults, and then implement appropriate repair measures to address the problem.

2) The locator is experiencing drift, which may be caused by external environmental interference or internal circuit issues. We can try adjusting the locator's sensitivity or gain to minimize the impact of external factors, while also inspecting the internal circuits to ensure they are functioning properly and maintaining the device's stability.

3) The locator display may be inaccurate due to incorrect sensor readings or issues with internal data processing. In this case, we need to recalibrate the sensor and verify that the data-processing algorithm is functioning correctly to ensure the accuracy of the locator display.

Through the above measures, we can effectively address various potential malfunctions that may occur during the locator's operation, ensuring it functions reliably and accurately.

1) A malfunction in the positioner circuit board can cause the valve to operate improperly.

2) Damage or wear to the small slide valve often results from insufficient cleanliness of the instrument air or the ingress of contaminants into the positioner, which in turn affects the valve's proper operation.

3) Damage to the proportional valve in the positioner can also lead to abnormal valve operation.

4) Damage to the sliding rheostat typically occurs due to excessively high ambient temperatures and the ingress of liquids like water into its internal components, which can lead to inaccurate valve positioning and abnormal operation.

5) If the O-ring at the air supply port of the positioner breaks, it will impede the movement of the small spool valve stem, causing the valve to fail to operate properly.

6) The gland connection of the locator has poor sealing, which could lead to moisture damage on the circuit board.

7) Severe pipe vibrations, excessively high ambient temperatures, and humidity can all lead to circuit board failures.

8) The gland head was not sealed tightly, allowing water to enter the locator and subsequently damaging the circuit board. To resolve this issue, reinforce the sealing performance of the gland head to prevent water from seeping into the locator.

9) High humidity and excessive dust in the instrument air cause dirt to enter the small slide valve, leading to wear and ultimately affecting the valve's proper operation. The recommended countermeasure is to install an additional air filter to improve the quality of the instrument air.

10) High ambient temperature, excessive humidity, and severe vibrations frequently cause the sliding rheostat and circuit board to fail. The solution is to separate the circuit board from the small slide valve and the sliding rheostat, designing a modular valve positioner instead.

11) The O-ring seal on the positioner is prone to cracking, which can cause the small spool valve stem to become stuck. This typically occurs due to excessively high air supply pressure—normal air supply pressure should be maintained around 0.5 MPa. To prevent this issue, the air supply pressure should be kept at approximately 0.4 MPa, and higher-quality seals should be selected.

IV. Failures Caused by Process and Design Factors, Along with Corresponding Countermeasures

Factors related to process and design can also lead to valve positioner failures. While these issues may not be as immediately obvious as mechanical or electrical faults, they still deserve careful attention. To ensure the reliable operation of valve positioners, we need to monitor these process- and design-induced failures closely and implement appropriate measures to prevent and address them effectively.

1) Fluctuations in process parameters caused the pipeline pressure differential to exceed normal ranges, resulting in the valve failing to operate properly.

2) Media factors cause scaling inside the valve body, leading to unstable valve operation.

3) Pipe blockage is another common reason why valves fail to operate smoothly.

4) Due to improper design selection, the selected actuator lacks sufficient torque to properly operate the valve. Additionally, the inappropriate choice of valve body material may also lead to damage to the valve body during operation.

5) When the control valve experiences excessive pressure differential and fails to open properly, an effective solution is to install a bypass valve on both the upstream and downstream sides of the control valve.

6) If valve body scaling occurs due to process issues, potentially affecting the proper opening of the control valve, you can install an additional flushing pipe and periodically disassemble the valve for cleaning. If necessary, the valve core may also need to be ground or polished.

7) If a pipeline blockage is hindering the operation of the control valve, optimize your operating procedures to minimize the likelihood of pipe clogging. Alternatively, disassembling the pipeline to flush the valve is also an effective solution.

8) For design selection issues, all process parameters should be thoroughly optimized during the design phase to ensure that inaccurate process parameters do not lead to problems when making the final selection.

V. DCS System-Related Failures and Corresponding Mitigation Strategies

FAQ Collection

As the core of modern industrial automation control, the stability of DCS systems is critical to production processes. However, due to various factors, DCS systems can occasionally experience failures, disrupting smooth operations. This article will explore common faults caused by DCS systems, along with their corresponding troubleshooting solutions, equipping you with the tools to better address and prevent these issues.

1) The I/O card is damaged, resulting in no signal output and, consequently, the control valve failing to operate.

2) Instability in the DCS output signal can cause fluctuations in the control valve opening, thereby affecting its proper operation.

6. Pneumatic Component Failures and Corresponding Mitigation Strategies

Pneumatic components are critical elements in control valve systems, and their damage or failure can directly affect the proper operation of the valves. To ensure stable system performance, it’s essential to implement effective strategies for preventing and addressing these issues.

1) Aging or damage to the air supply hose, or leaks in the stainless steel air supply pipe, can result in insufficient air pressure, which in turn affects the proper operation of the control valve.

2) If the air filter breaks or its filter element becomes excessively dirty, it can also interfere with the smooth operation of the control valve.

3) Insufficient air supply pressure, or the air source simply not being turned on, is also a common cause of abnormal control valve operation.

To address these potential issues, we propose the following strategies:

1) Regularly inspect the condition of gas supply hoses and stainless steel gas lines, promptly replacing any aged or damaged components to ensure stable gas pressure.

2) Ensure the air filter remains intact and regularly clean or replace the filter element to maintain the precise operation of the control valve.

3) Continuously monitor the air supply pressure to ensure it remains within the normal range, and verify that the air source is properly activated, thereby maintaining stable operation of the control valve.

In response to the issues mentioned above, we can implement the following measures for improvement:

1) Replace the air supply hose or air filter with higher-quality components, and establish a regular inspection schedule. If any damage, air leakage, or excessive dirt is detected in the air supply hose, air filter, or filter element, immediate replacement should be carried out to ensure proper operation of the control valve.

2) Adjust the air supply pressure to reach the minimum required by the pneumatic valve, ensuring stable operation of the control valve.

Keywords: Control Valve Failure Analysis and Solutions

Related News

Company Training

Company News

-

ChuanKai Valves is actively responding to the new regulations, and the process of obtaining the type-test certification is nearing completion.

Time:2024-10-18

-

The new <Type Test Rules for Pressure Piping Components> has been released, paving the way for new industry advancements.

Time:2024-10-18

-

A batch of valves delivered by XX Gas Corporation

Time:2025-11-25

-

[China Eastern Electric Group Dongfang Electric Motor Co., Ltd.] Shielded Pump Division – Valve Procurement: Award Announcement

Time:2025-10-31

-

A batch of valves delivered by XX Chemical Co., Ltd.

Time:2025-10-31

-

XX Research Institute Project Valve Delivery

Time:2025-10-24

-

Commemorative Event Marking the 80th Anniversary of the Victory in the Chinese People's War of Resistance Against Japanese Aggression and the World Anti-Fascist War

Time:2025-09-05

-

Notice on Providing Free On-Site Fault Diagnosis Services for Control Valves

Time:2025-08-28

-

Introduction to the National Standard for Valves

Time:2024-10-15

-

The Structure and Features of All-Welded Ball Valves

Time:2023-06-09

-

Key points for installing and the working principle of large-caliber gate valves

Time:2023-06-09

-

How an Ammonia Globe Valve Works and How to Use It

Time:2023-06-09

-

Installation Method for Lift-Type Check Valves

Time:2023-06-09

Industry News

-

Do you already know everything about ball valves?

Time:2023-06-09

-

Technological innovation drives development—let's strive to be the industry leader.

Time:2023-06-09

-

Seize the opportunities of the times and rise with the momentum.

Time:2023-06-09

-

Industrial ultra-low-temperature valves no longer rely on others.

Time:2023-06-09

-

What is mechanical manufacturing? The nature of the mechanical manufacturing industry.

Time:2023-06-09