Installation Method for Lift-Type Check Valves

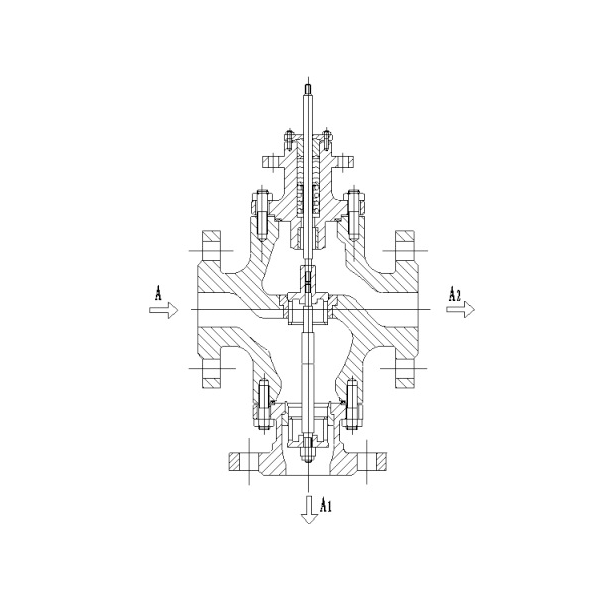

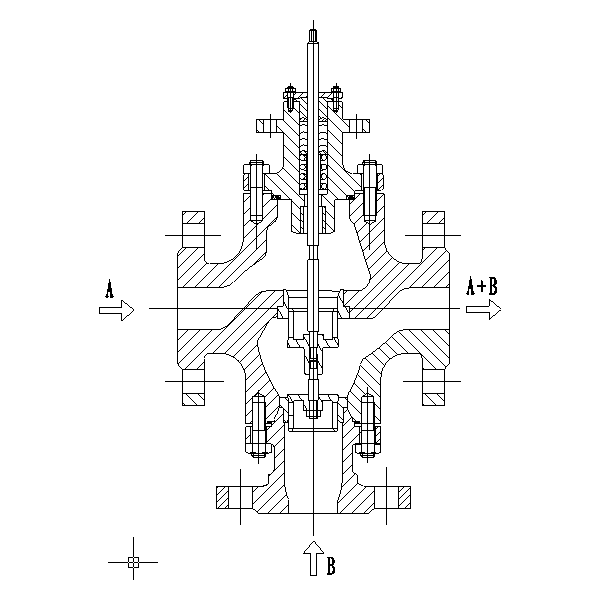

The function of a check valve is to allow the media to flow in only one direction, while preventing backflow. Typically, these valves operate automatically: when fluid flows in the forward direction, the pressure pushes the valve disc open; however, if the fluid tries to flow backward, the combined force of the fluid pressure and the disc’s own weight closes the disc against the valve seat, effectively stopping the flow.

Among the types of check valves, the internal-threaded check valve and the butterfly check valve fall into this category. Specifically, they include two subtypes: the swing check valve and the lift check valve.

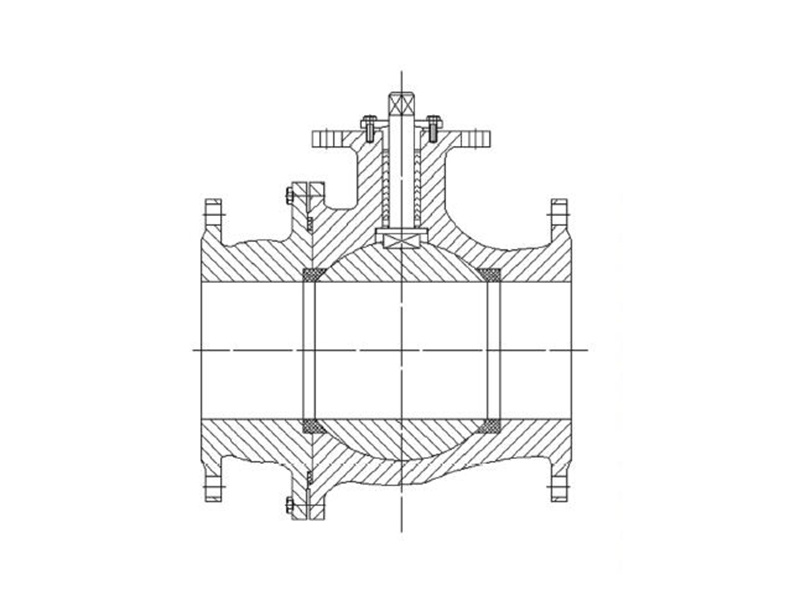

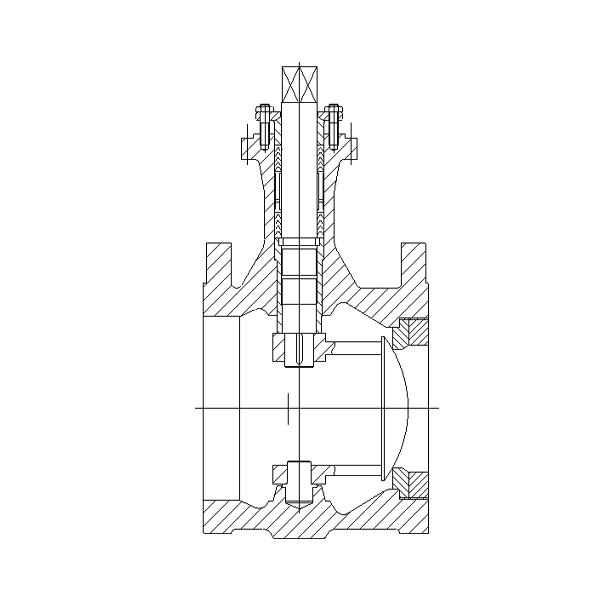

The swing check valve features a hinged mechanism and a door-like disc that rests freely on an angled valve seat surface. To ensure the disc always lands precisely at the right position on the seat, the design incorporates a hinge system that provides ample clearance for the disc to swing open and closed—allowing full, even contact with the seat. The disc itself can be made entirely of metal, or it may have a resilient lining—such as leather, rubber, or even a synthetic coating—depending on the specific performance requirements of the application.

When fully open, the swing check valve offers minimal resistance to fluid flow, resulting in a relatively low pressure drop across the valve.

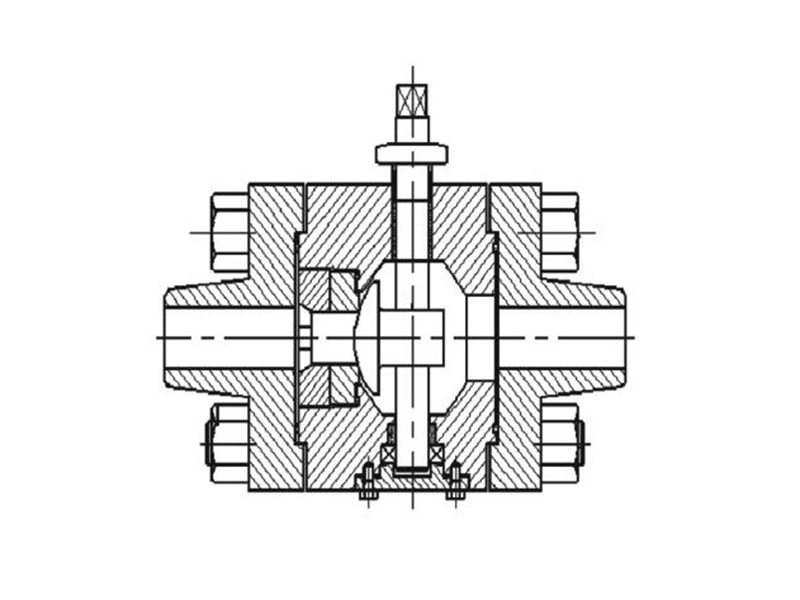

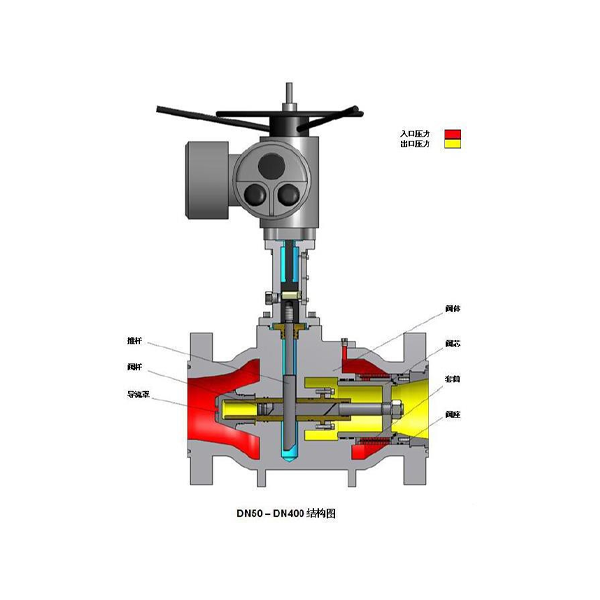

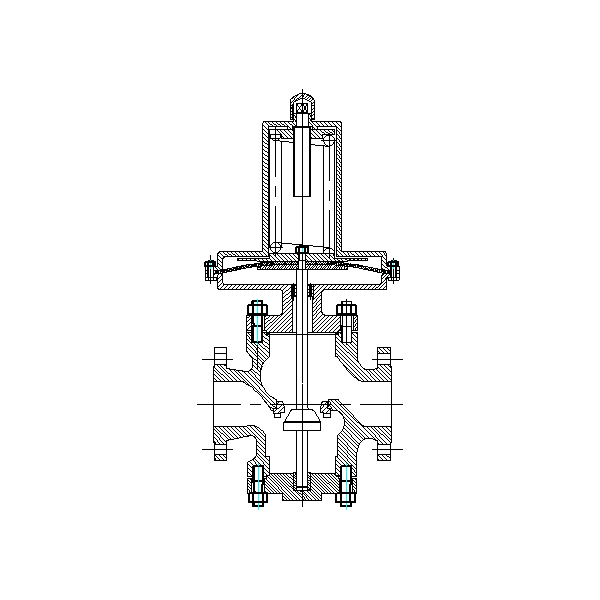

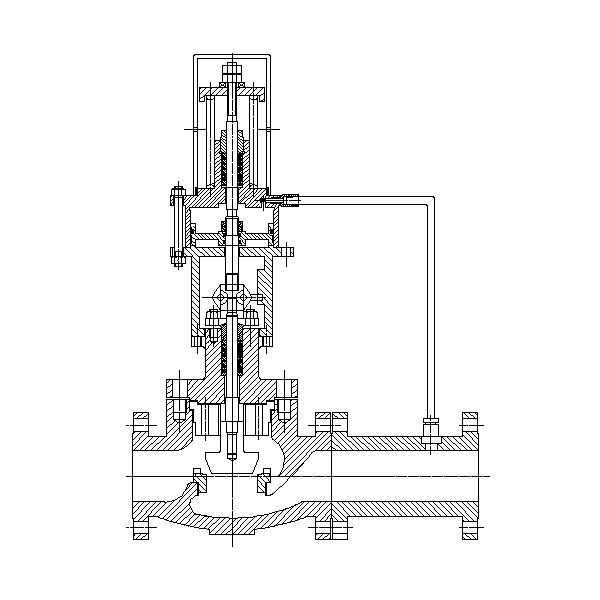

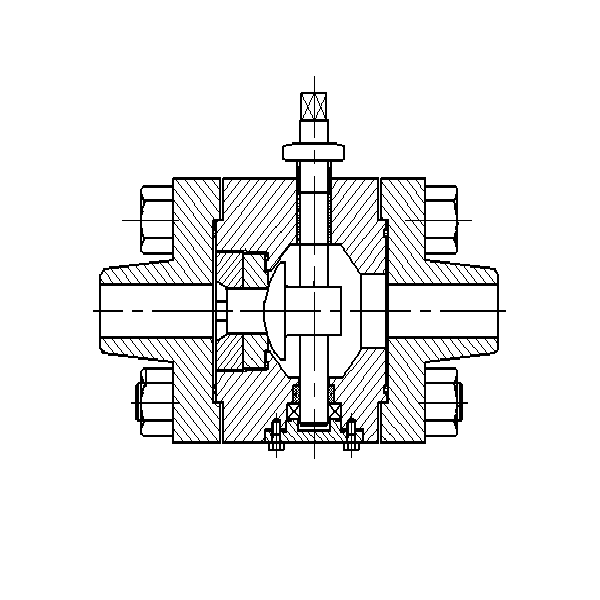

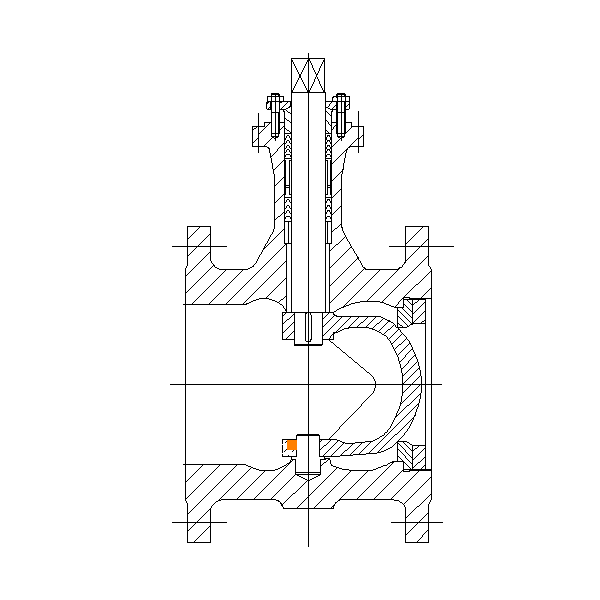

In contrast, the lift check valve has a disc that sits directly on the sealing surface of the valve body’s seat. Like a globe valve, this type of check valve allows the disc to move freely up and down. When fluid flows in the forward direction, the pressure lifts the disc off the seat, permitting flow. Conversely, if backflow occurs, the disc returns to its seated position, blocking the reverse flow.

Depending on the operating conditions, the disc can either be constructed entirely of metal or fitted with a rubber gasket or rubber ring mounted on a disc holder. Similar to globe valves, the flow path through a lift check valve is narrower, which leads to a slightly higher pressure drop compared to the swing check valve. Additionally, the swing check valve imposes far less restriction on flow, making it more efficient for applications requiring unrestricted passage.

2023-06-09

![[China Eastern Electric Group Dongfang Electric Motor Co., Ltd.] Shielded Pump Division – Valve Procurement: Award Announcement [China Eastern Electric Group Dongfang Electric Motor Co., Ltd.] Shielded Pump Division – Valve Procurement: Award Announcement](https://omo-oss-image.thefastimg.com/portal-saas/pg2025091920292512287/cms/image/3999e8cd-dbf4-4be3-b0f5-4b8e64829f22.png)